Unlike any other in the industry, Secure Mobile periodically conducts testing of its ballistic materials and the entire armored vehicles that often exceed the requirements set by the certifying agencies and laboratories. Such tests are also conducted to determine how many rounds a material can actually take using different high-power weapons before penetration occurs, at what angles they occur, and at what grain/weight of the round.

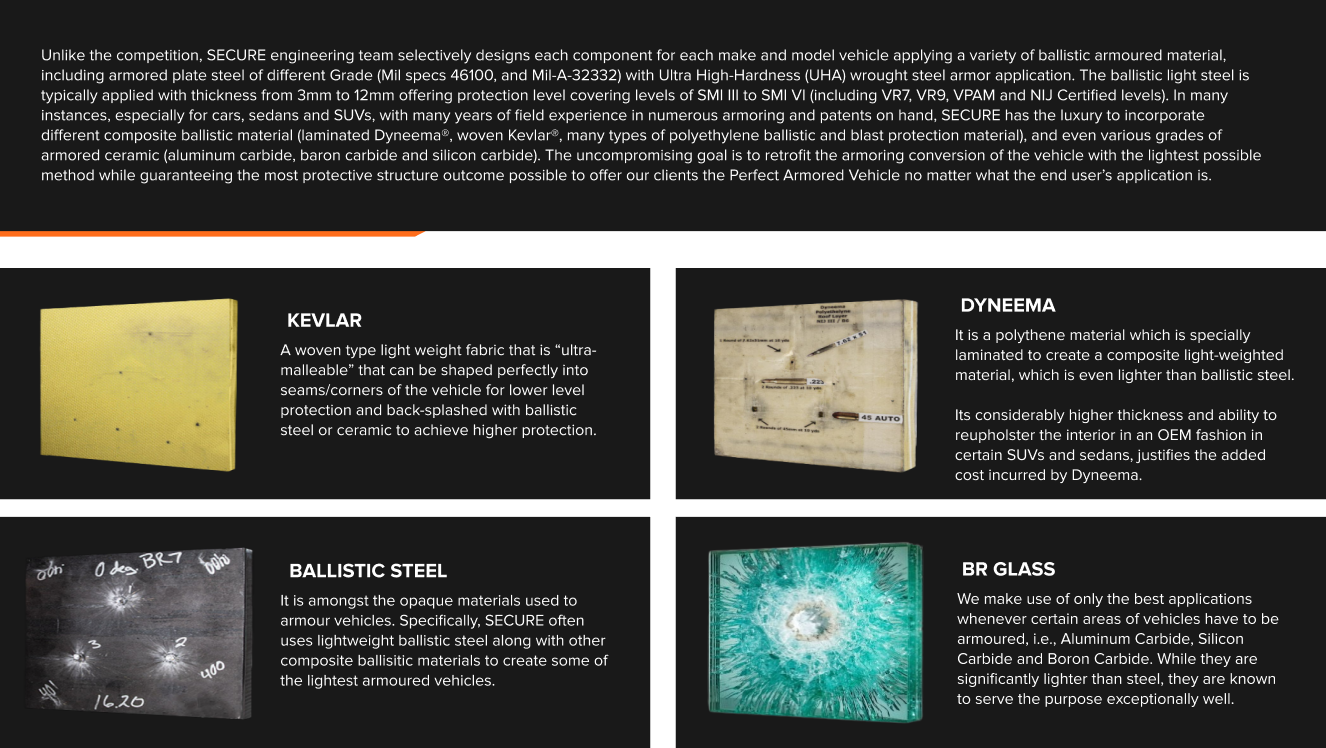

Secure Mobile prides itself in using a broad range of high-grade certified ballistic opaque materials applied throughout the vehicles. A combination of lightweight Kevlar and Dyneema are often used for selected model SUVs and sedans in addition to ballistic steel. Continuous ballistic testing of the material is also conducted to determine how the material will hold up under extreme lines of fire using various high power weapons and different grain/velocity rounds.

Through decades of experience and exclusive relationships with selected high-quality ballistic glass manufacturers, Secure has carefully designed its no-spall glass and polycarbonate layers for each make and model vehicles to significantly prevent or minimize delamination from occurring while maximizing optics.

The manufacturing of armoured vehicles is a highly specialized field requiring not only experienced and uniquely skilled technicians, fabricators, and certified welders, but also the availability of the latest equipment permanently at disposal to quickly produce the perfect cuts and components for each piece of armoring structure requiring its own unique application. This is achieved by utilizing the latest make and models laser machine, water jet, plasma cutter, and sophisticated CNC machine while applying numerous types of precision techniques to fabricate the exact and perfect ballistically armored piece per each engineered CAD drawing. SECURE is proud to lead the field of armoring of vehicles offering its clients the latest in-house available technology unmatched in the industry.

For over the past three decades, with manufacturing plants of well over 200,000 square feet capacity, SECURE has successfully managed the integration and manufacturing of its armored SUVs, armoured sedans & automobiles, and armored trucks to meet the increasing demands of the discerning VIP clients requiring custom-armoring with exclusive specifications. SECURE is equally positioned to handle mass production of up to 30 vehicles per month orders This setup is designed to meet any anticipated larger orders with an even faster production timeline to meet each special client’s requirements. Selected orders, as deemed necessary, are exclusively retrofitted at our secured and dedicated area of the plant.

A-20 Adhyapak Nagar,

Najafgarh Road, Nangloi, Delhi-41

A-20 Adhyapak Nagar,

Najafgarh Road, Nangloi, Delhi-41

+91-9811251496

+91-9811251496 +91-11-25944555

+91-11-25944555 contact@securemobileindia.com

contact@securemobileindia.com

www.securemobileindia.com

www.securemobileindia.com